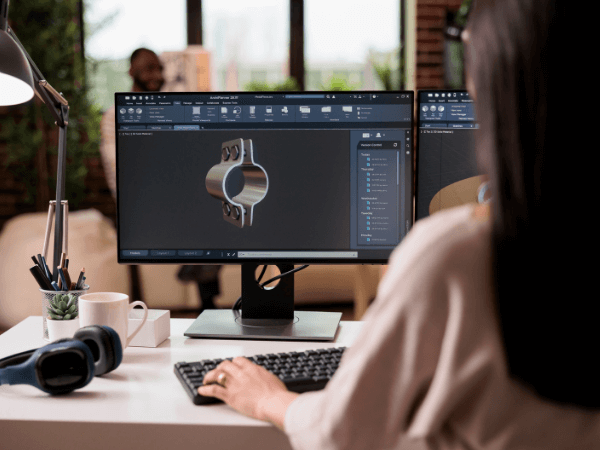

PolyJet 3D printing is an advanced technology that uses inkjet printing and UV light to create precise, multi-material parts. This method is perfect for producing high-resolution prototypes, molds, and functional parts that demand exceptional detail and accuracy.

Poly-Jet Fusion technology works by using a specialized print head to deposit a thin layer of liquid photopolymer onto a build platform. As each layer of material is laid down, a UV light source immediately cures the photopolymer, solidifying it and allowing the process to continue layer by layer. This method ensures the creation of highly detailed, high-resolution parts with exceptional accuracy.

The process is repeated for each subsequent layer, building the part from the ground up. Poly-Jet Fusion’s ability to work with multiple materials simultaneously makes it ideal for creating complex parts that require varying properties, such as flexibility, transparency, or high strength. The result is precise, multi-material components suitable for a range of applications, from prototyping to functional end-use parts.

Poly-Jet Fusion offers several advantages over other 3D printing methods, such as:

High Precision

With resolutions as fine as 16 microns, Poly-Jet Fusion creates parts with exceptional detail, rivaling traditional injection molding.

Multi-Material Capabilities

This technology can print with various materials simultaneously, enabling the creation of parts with distinct properties like flexibility, transparency, or strength.

Quick Production

Poly-Jet Fusion significantly reduces production time, delivering high-quality parts within hours, far faster than traditional manufacturing processes.

While Poly-Jet Fusion offers many advantages, it also has some limitations. One major challenge is that the technology is still relatively new, meaning it is not as widely accessible as more established 3D printing methods. This can limit the availability of service providers who specialize in this process. Additionally, Poly-Jet Fusion printers are generally more expensive compared to other 3D printing systems, making the initial investment quite high for businesses.

Another limitation is the post-processing requirements. While the technology allows for high-quality, multi-material prints, parts often require additional cleaning and curing after printing. This adds time to the production process and may increase the overall cost. Despite these challenges, Poly-Jet Fusion remains an excellent option for creating highly detailed, multi-material parts when precision and material variety are essential.

Poly-Jet Fusion is a versatile 3D printing technology with a wide range of applications, including:

Prototyping

Poly-Jet Fusion allows for the creation of high-quality, detailed prototypes, which is ideal for product design validation and testing.

Molds

The technology is highly effective for creating precise molds used in injection molding, casting, and other manufacturing processes, enabling quick production cycles.

End-use parts

Poly-Jet Fusion can produce durable, functional parts used across various industries, including healthcare, automotive, aerospace, and consumer electronics, making it suitable for both prototyping and low-volume production.