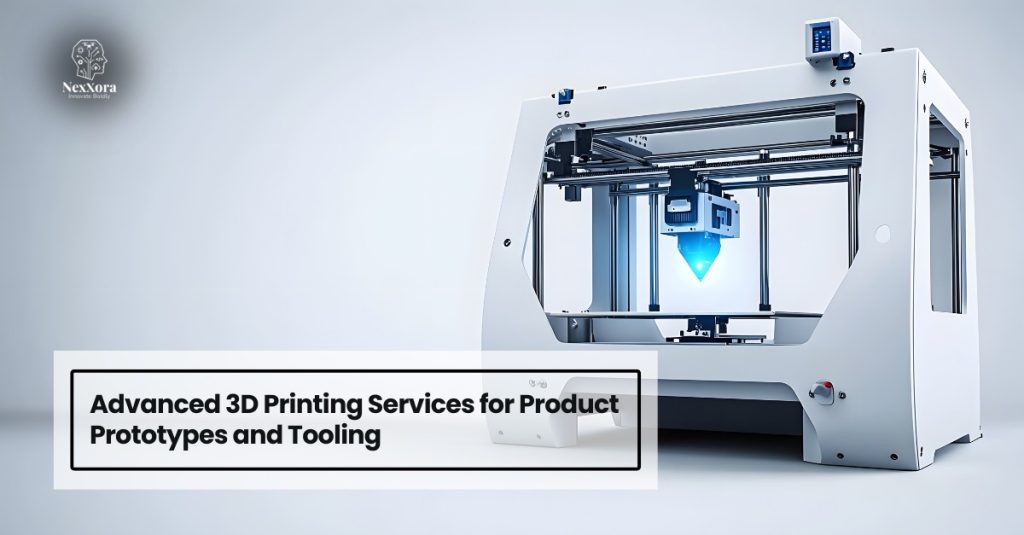

In the world of engineering and product development, where everything is moving too fast today, the conversion of ideas into real products has quickly become a necessity rather than a luxury. Chennai, the place that is on the way to becoming a strong center for engineering and manufacturing excellence, is raising the need for advanced prototyping solutions that cut down on time-to-market and at the same time enhance the design accuracy. The advanced 3D printing services in Chennai are the ones that play an important role here.

Nexxora Tech brings the conceptual design and real-world production very close to one another by providing precision-driven 3D printing solutions that support the innovations of various industries. By employing the most modern additive manufacturing technologies along with the application of engineering skills, Nexxora Tech makes it possible for companies to go smoothly from design to reality.

Understanding Advanced Prototyping in Modern Manufacturing

The advanced prototypes are not just the visual models or mock-ups. They are the production of very accurate, functional, and test-ready components that are almost like the parts being produced for sale. These prototypes permit the engineers and designers to assess the factors of performance, form, fit, and manufacturability during a trial run before the go-ahead is given for large-scale production.

With advanced 3D printing, not only the external and very complex shapes but also internal structures and even the most delicate features can be made with exceptional precision. Traditional manufacturing methods find it a struggle to come out with such accuracy in early designs.

The Role of 3D Printing in Product Development

3D printing has made a fundamental change in the way the product designing and developing processes are done. Instead of time-consuming processes along with high upfront costs, the additive manufacturing technique permits the components to be built layer by layer, directly from digital models.

This method promotes:

- Faster development cycles

- Reduced material

- Greater design freedom

- Cost-effective experimentation

For companies aiming to stay competitive, 3D printing is no longer an option; it is a strategic advantage.

Functional Prototypes: Testing Beyond Appearance

One of the main benefits of using advanced 3D printing services is the possibility of creating functional prototypes. These functional prototypes are not only for show; they are real parts with the design and functionality to endure the real world.

Functional prototypes are providing great help for businesses:

- Testing the mechanical strength and also the lifespan of the product

- Checking and possibly confirming thermal and chemical resistance

- Evaluating assembly compatibility

- Mimicking real usage scenarios

At Nexxora Tech, functional prototypes are made with materials of the same quality as the final production ones, thus allowing reliable testing and easy decision-making.

Precision Manufacturing Models for High-Accuracy Applications

Precision is crucial in areas such as automotive, aviation, electronics, and medical devices. Thus, precision manufacturing models created through advanced 3D printing ensure tight tolerances, consistent quality, and dimensional accuracy.

Particularly, these models are good for:

- Checking component fit and clearance

- Simulating assembly line processes

- Creating custom tooling and fixtures

- Running low-volume production

Nexxora Tech uses high-resolution printing technologies to provide manufacturing models that comply with the toughest engineering requirements.

Engineering Design Validation through 3D Printing

Before a product moves to mass production, engineering design validation is essential. Advanced 3D-printed prototypes allow engineers to identify design flaws early and reduce costly revisions later in the production cycle.

Through design validation, organizations can:

- Confirm the structural integrity

- Judge the ergonomics and usability

- Find stress points and failure risks

- Increase the material efficiency

By validating designs at an early stage, Nexxora Tech facilitates the process of businesses getting more efficiency in production and improves product reliability while minimizing the development risks.

Rapid Product Iteration: Accelerating Innovation

In the race of competition, speed is the name of the game. Thanks to the innovation of rapid product iteration, the use of advanced prototyping lets the teams swiftly fine-tune their designs based on the feedback from the tests.

By 3D printing:

- The design changes can be made in a few hours

- Different variations can be simultaneously tested

- The innovation cycles are shorter and more efficient

Nexxora Tech backs up the agile product development process by permitting faster iterations with no compromise on either quality or accuracy, thus assisting enterprises in ushering in the next generation of products sooner.

Industries Benefiting from Advanced 3D Printing in Chennai

Advanced 3D printing services are used by a variety of industries, such as

- Automotive and electric vehicles

- Aerospace and defense

- Industrial machinery

- Consumer electronics

- Healthcare and medical devices

The combination of the strong engineering ecosystem in Chennai and the expertise of Nexxora Tech makes it a perfect place for next-generation manufacturing solutions.

Why Choose Nexxora Tech for Advanced 3D Printing Services?

Nexxora Tech is a comprehensive solution provider offering both advanced printing services and extensive prototyping support tailored specifically to meet diverse engineering objectives. Nexxora Tech, with the help of advanced prototyping, functional accuracy, and manufacturing readiness, is able to provide businesses with the efficient and reliable transformation of ideas into production-ready solutions.

Backed by the global expertise and innovation-driven approach of Nexxora Inc., Nexxora Tech integrates international best practices and advanced engineering standards into every 3D printing and prototyping project.

Conclusion

The whole life cycle of moving a concept to a product requires accuracy, quickness, and creative ideas. In Chennai, the cutting-edge 3D printing services are changing the way companies view product development, and Nexxora Tech is leading this change. It provides functional prototypes, precise manufacturing models, validation of engineering design, and quick product iterations, which allow the organizations to transit from design to reality with full confidence.

Future-ready manufacturing setups will definitely have to rely on advanced prototyping as one of the main pillars of their success, and Nexxora Tech will be one of the supporting giants when such an era comes.

Frequently Asked Questions (FAQ)

- What is advanced prototyping in 3D printing?

Advanced prototyping is the process of making prototypes that are very precise and functional and that are very similar to the parts that will be produced at the end of the process, thus allowing for real-world testing and validation.

- How do functional prototypes differ from visual prototypes?

Functional prototypes are made to work in a mechanical and structural way, while visual prototypes are concerned mainly with the appearance and shape.

- Can 3D printing be used for engineering design validation?

Of course. Advanced 3D printing is one of the most widely used methods for engineering design validation that allows testing performance, strength, fit, and usability before mass production.

- What are precision manufacturing models?

Precision manufacturing models are 3D-printed components of the highest accuracy and used for testing assemblies, tooling, and production feasibility.

- How does rapid product iteration benefit businesses?

Rapid product iteration gives companies the opportunity to make quick design changes, thus reducing development time and cost and bringing the new and improved products to the market quicker.

- How does Nexxora Tech ensure precision in manufacturing models?

Nexxora Tech adopts high-resolution 3D printing processes along with strict quality checks to produce precision manufacturing models. This guarantees dimensional accuracy, narrow tolerances, and uniformity necessary for verifying assembly and evaluating tools.

No comment