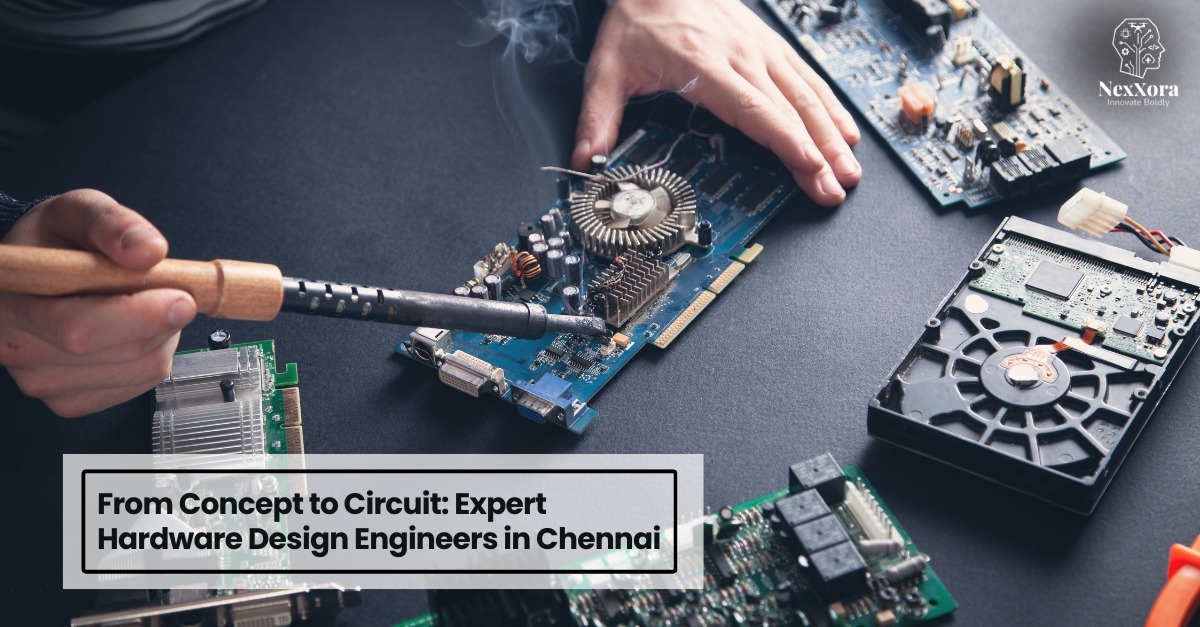

In today’s fast-evolving technology ecosystem, hardware design has matured into a highly structured and data-driven discipline, drawing on electronics engineering, embedded systems, manufacturing science, and supply-chain strategy. Products are increasingly smart, compact, and connected, necessitating a structured development framework combined with experienced engineering talent within organizations.

At NexXora, this is a change brought in by domain experts-innovators in hardware design engineer in chennai operating at the juncture of innovation, reliability, and scalability.

- Decoding the Modern Hardware Design Process

- Phase 1: Conceptual Engineering & Requirement Intelligence

- Phase 2: Prototyping & Engineering Validation

- Phase 3: Design Refinement & Engineering Optimization

- Phase 4: Production Engineering & Supply Chain Alignment

- Phase 5: Market Launch & Scalable Deployment

- Continuous Improvement Across the Product Lifecycle

- Avoiding Common Pitfalls in Hardware Engineering

- Why NexXora Is a Trusted Hardware Engineering Partner

- Conclusion: Building Smarter Products with a Future-Ready Hardware Design Process

Decoding the Modern Hardware Design Process

Today’s hardware design process is no longer a linear workflow but an iterative lifecycle that brings together system architecture definition, simulation, prototyping, validation, and production engineering. Key technologies such as AI-assisted PCB routing, digital twins, and advanced power integrity analysis are playing a crucial role in reducing design risk and accelerating time-to-market.

NexXora’s approach ensures that every design decision has a basis in simulation data, lifecycle awareness, and manufacturability insights.

Phase 1: Conceptual Engineering & Requirement Intelligence

Market-Driven Requirement Definition

A successful hardware design involves a clear definition of requirements in a tangible manner. This is a phase in hardware design whereby customer requirements, regulatory requirements, and environments are translated into requirements based on functions, electricity, and mechanics.

Advanced analytics and benchmarking capabilities of a competitor help to keep products relevant to real-world consumption and scalability.

System Architecture & Technical Blueprinting

The system architects, during this stage, specify the technical backbone of the product with regard to:

- Selection of processor and chipset (MCU, MPU, AI accelerators)

- Power distribution and thermal management strategy

- High-speed interfaces/communication protocols: USB, Ethernet, CAN, SPI, Wi-Fi and BLE.

This architectural rigour allows a hardware design engineer in Chennai to balance performance, power efficiency, cost and long-term availability.

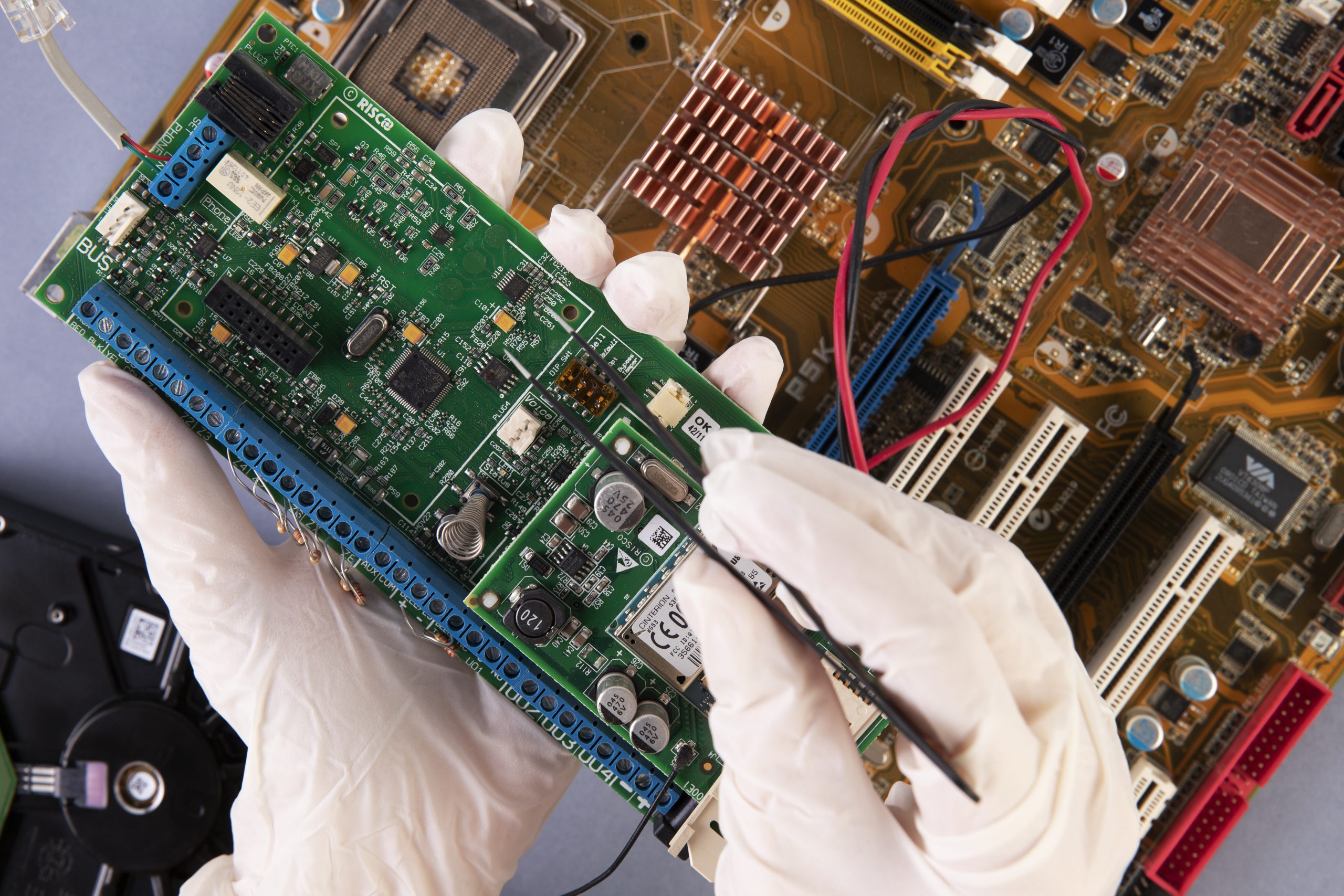

Phase 2: Prototyping & Engineering Validation

Rapid Prototyping and Simulation-Driven Design

Rapid PCB prototyping, along with signal-integrity and power-integrity simulations, paves the way for early design validation of complexities. AI-enabled EDA tools further smoothen the road to layout optimization and reduce iteration cycles.

These practices significantly improve the predictability of the hardware design process.

Functional, Electrical & Environmental Testing

Validation extends beyond basic functionality to include:

- Electrical margin and stress testing

- Thermal and vibration analysis

- Environmental stress screening (ESS)

Such multi-layer testing ensures reliability across varied operating conditions.

Phase 3: Design Refinement & Engineering Optimization

Design for Manufacturing (DFM) and Assembly (DFA)

The DFM and DFA methodologies are integrated right from the start to facilitate the designing of PCB layouts, the creating of component footprints, and the planning of assembly workflows. Consequently, it leads to a decrease in manufacturing defects, an increase in yield, and an easier setup of automated processes for mass production.

Cost Optimization & Value Engineering

BOM optimization, component lifecycle analysis, and alternative sourcing strategies are the main tools that NexXora uses to guarantee that cost efficiency is reached without any compromise on performance or quality, which is an important factor for scalable hardware programs.

Phase 4: Production Engineering & Supply Chain Alignment

Manufacturing Readiness & Pilot Builds

Designs undergo EVT, DVT, and PVT builds before mass production to validate their performance in production conditions. This process guarantees that the change from prototype to high-volume manufacturing is over without any problems.

Supply Chain Strategy

Resiliency is the major requirement of contemporary supply chains. To reduce the risks and to guarantee continuity, NexXora incorporates component availability, lead-time forecasting, and multi-vendor sourcing right into the hardware design process.

Phase 5: Market Launch & Scalable Deployment

Quality Assurance, Compliance & Certification

Final validation incorporates EMC, safety, and environmental compliance tests. Consistent quality across production batches, thereby allowing global deployment with confidence, is guaranteed by automated inspection systems and traceability frameworks.

Continuous Improvement Across the Product Lifecycle

Final validation incorporates EMC, safety, and environmental compliance tests. Consistent quality across production batches, thereby allowing global deployment with confidence, is guaranteed by automated inspection systems and traceability frameworks.

Avoiding Common Pitfalls in Hardware Engineering

Issues like last-minute design change inputs, unaddressed doc requirements, and manufacturing misalignments are quite common in such projects. NexXora ensures all this is avoided through design review, cross-functional collaboration, and early manufacturing involvement, which is practiced by all hardware design engineers in Chennai.

Why NexXora Is a Trusted Hardware Engineering Partner

NexXora can be relied upon as a hardware engineering partner due to its technical expertise and pragmatic methodology in designing products. The engineering professionals of NexXora utilize advanced design methodologies such as system-level architecture planning and simulation-driven validation in their designing efforts.

What makes NexXora stand out is its capacity to close the design-manufacturing deficit. Through the integration of the concept of Design for Manufacturing (DFM), Design for Assembly (DFA), and the idea of Design for Testability (DFT), NexXora makes the scale-up process easier while providing hardware solutions that are appropriate for the modern industry era.

Conclusion: Building Smarter Products with a Future-Ready Hardware Design Process

With the ever-advancing world of technology, a future-ready hardware design methodology has to implement innovation with the principles of reliability, speed, and scalability in a balanced manner. NexXora has an organized and agile-based methodology in the developmental process of design, validation, and readiness for manufacturing.

Through the integration of advanced engineering expertise, NexXora assists companies in the successful development of hardware products that can effectively enter the marketplace based on their innovative designs.

No comment